Public

MMC Packaging Catalog

MMC Packaging Jobs

MMC Packaging Locations

MMC Packaging News

MMC Packaging Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

MMC Packaging: The Cap Lining Expert

“This newest addition to our already wide selection of cap lining systems was developed based upon input from our many valued customers.”

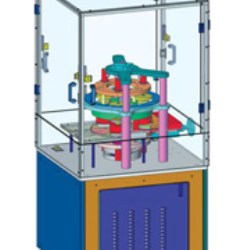

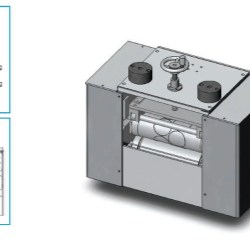

The basic principal of our standard cap lining machines is to utilize a multi-station rotary indexing machine to receive parts into a pocket wheel in multiple lanes. Each cap is fed into an individual pocket wheel in the pocket wheel in order to maintain positive control of each part while it is being processed through the machine. Each of our cap lining machines has individual, dedicated stations.

MMC Packaging: The Cap Lining Expert

“This newest addition to our already wide selection of cap lining systems was developed based upon input from our many valued customers.”

The basic principal of our standard cap lining machines is to utilize a multi-station rotary indexing machine to receive parts into a pocket wheel in multiple lanes. Each cap is fed into an individual pocket wheel in the pocket wheel in order to maintain positive control of each part while it is being processed through the machine. Each of our cap lining machines has individual, dedicated stations.

Overview | |

| Machine Type | Machinery. Processing, Assembly Equipment. Closing, Seaming, Sealing Machinery |

|---|---|

Notes

| |

General | |

| Dependencies | Electrical Supply |

|---|---|