Public

MMC Packaging Catalog

MMC Packaging Jobs

MMC Packaging Locations

MMC Packaging News

MMC Packaging Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

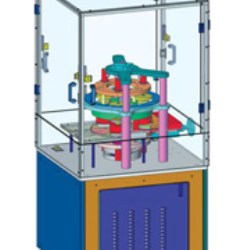

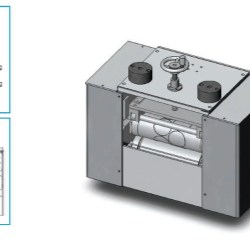

MMC Packaging Equipment, a Tekni-Plex business, will be highlighting its new high-speed (up to 2,400 parts per minute) closure slitting and band folding machine at K 2019, October 16-23, Dusseldorf, Germany, Hall 13 / C73.

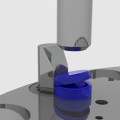

The new generation turnkey solution is ideal for plastic beverage closure manufacturers who perform a post-molding process of slitting and folding tamper-evident bands for closures ranging in size from 24 to 38mm.

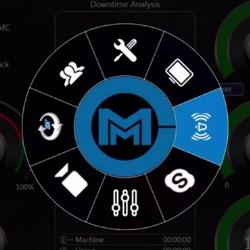

“MMC has been supplying closure slitters to the industry for more than 25 years. We have now developed a new generation of high speed slitting that has been engineered with Industry 4.0 attributes to optimize manufacturing,” said Christiane El-Tekly, general manager. “This includes a broad array of functions including overall equipment performance, detailed inspection and production data and remote support access.”

The system also features a six-camera vision inspection to help meet quality objectives. The vision checks include closure integrity, closure contamination, bore seal gaging and cavity number recognition. The machine offers superior tracking capabilities and a patented spark inspection unit for pinhole detection at the injection point. A cap counting accumulation and boxing system is designed to avoid upstream process interruption.