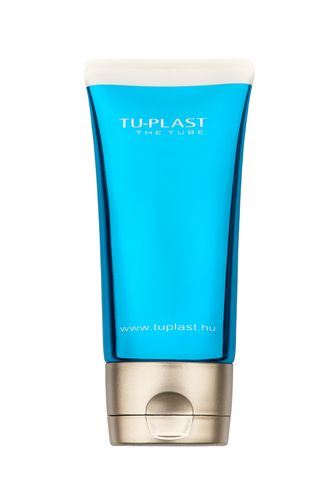

Hot foil stamping is a highly attractive and favourable tube decoration form to enhance luxury cosmetic products. Tu-Plast has invested in this technology and through the experience gained by the company, is able to offer its customers a tube that is fully covered in hot foil, even right to the tube neck.

Tu-Plast offers full body hot foil stamping decoration for both cylindrical and oval tubes, proving an ideal decoration option for special gift items or beauty products that reflect prestige through the quality of the packaging decoration.

An oval tube with full body hot foil stamping and a stylish cap are an excellent way to express the values and uniqueness of a product and ensure brand differentiation.

.jpg)