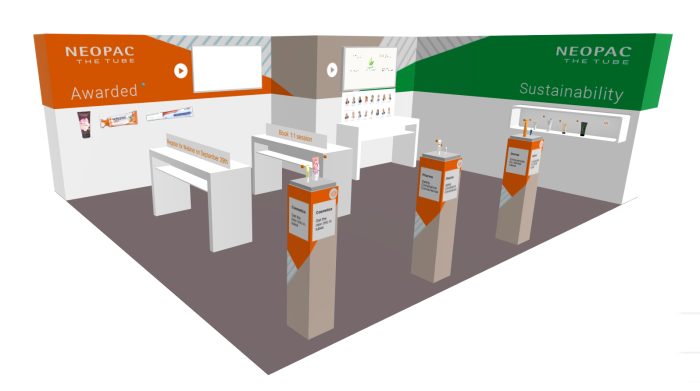

Neopac, a global provider of high-quality packaging for a broad array of industries and applications, will showcase its full portfolio of tubes at Webpackaging LIVE, a virtual exhibition billed as a modern alternative to physical shows. Offering international exposure, the extended exhibit – participants have their products featured from September 1 through November 30 – employs 3D technology to optimally showcase a wide variety of packaging solutions for a broad array of applications, including cosmetics, pharma, dental, and more.

One of Neopac’s marquee tube lines is the company’s EcoDesign portfolio. Primarily for cosmetics and personal care applications, the collection includes the Recycled Tube featuring 64% recycled, “FDA food-contact” compliant polyethylene plastics; Sugarcane Tube, made from renewable raw materials and offering the same characteristics and processability as fossil-based polyethylene; and PICEA™ wood tube, comprised of 95% renewable material in the tube body and shoulder – including 10% of spruce wood from wood waste in sawmills.

Neopac also will showcase its recently introduced SpringTube™, a packaging solution for cosmetics and personal care products. Developed by subsidiary 3D Neopac, the tube is specially designed to maintain its shape while delivering a host of additional benefits for consumers, brand owners and manufacturers. Featuring a tamper-evident, push-on flip-top cap, the printer-friendly SpringTube™ can be decorated via digital, flexo and metallic foil processes. For product protection, an ethylene vinyl alcohol (EVOH) barrier preserves oxygen-sensitive formulas, and helps extend the shelf life of beauty and personal care products.

.jpg)