If this is your company, CONTACT US to activate Packbase™ software to build your portal.

We have been the precursors of the PET use for cosmetic packaging: this for the development of the mascara plastic brush and again for the use of thermoplastic/elastomer blend in order to reach particular tactile effects. The same attention that we put in the research of new aspects of technology is also reserved to the project developments: Pibiplast uses the most recent software for 2D & 3D design.

Development also means paying very close attention to the costs of the product. Only through the maximum standardization of the technical solutions can we obtain a well known product with quality, a reasonable price and a development & realization timetable in line with the market's demands as timing is becoming more and more important.

It is for that reason that Pibiplast, by company choice, is constantly investing in the realization of new “Standard Lines” and places them at the disposal of everyone who is counting on our company’s capabilities.

Pibiplast has the essential know-how and technology to work with every thermoplastic raw materials (both technical and aesthetical), which are normally used in the Cosmetic Packaging Industry (such as PET, ABS, PET, LDPE, HDPE, PETG, PMMA, POM, PP, PVC, SAN).

Our technologies are:

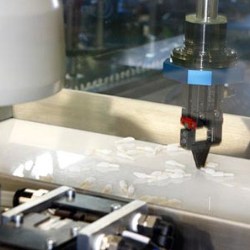

- injection moulding (mono-inj. and bi-injection):

machine from 60t to 350t - extrusion-blow moulding: machines can produce

bottles from 3ml to 1500ml - injection-blow moulding: different types of machines that can have multi-cavities (10/12) moulds

- injection-stretch-blow moulding: machines with different productive capacities able to satisfy the highest quantity/quality needs

- traditional silk screening (from 1 to 5 colours/passes)

- UV silk screening (until to 6 colours)

- ink pad printing

- spray varnishing

- sleever

Furthermore there is an operating technical office for the development and the execution of all automation elements in order to ensure the customer a high industrial level with costs under control, qualitative guarantee and flexible productivity.

We make use of a 3D design software in order to create a full-scale prototypes so that the customer can evaluate the requested product before its industrialization.

The strong desire to continuously improve the performance of our products pushes Pibiplast SpA to systematically do quality checks during the process and to optimise its services. During the production every process step is regularly checked according to its acquired experiences and its evolving know-how.

Only after the planned quality checks is the product declared fit and is stocked in our warehouse. On top of all that comes our commitment to consistently optimize the company’s processes. In this way we can always guarantee the best quality and we can satisfy our customer’s highest quality requirements. Quality, security and environment preservation are Pibiplast’s essential values.

CERTIFICATION

Pibiplast's Quality System is made and based upon ISO 9001:2008.

The need to preserve the environment is becoming a major concern in the Manufacturing World. Markets prove to be even more willing to award the use of technologies or materials with a minimum impact on the environment.

These aspects are fundamental to Pibiplast since we work in the Cosmetic Packaging Industry. As proof of the great priority we attribute to the environment, during this last year Pibiplast has continuously researched raw materials in order to develop new biodegradable and renewable components.