Public

Robinson Capabiities

Robinson Packaging Catalog

Robinson Packaging Documents

Robinson Packaging Gallery

Robinson Packaging Innovation Videos

Robinson Packaging Locations

Robinson Packaging News

Robinson Packaging Showcase 3D Models

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Huhtamaki Inc. is a global player in sustainable food-on-the-go and food-on-the shelf packaging solutions, operating in 35 countries from 81 sites across the world.

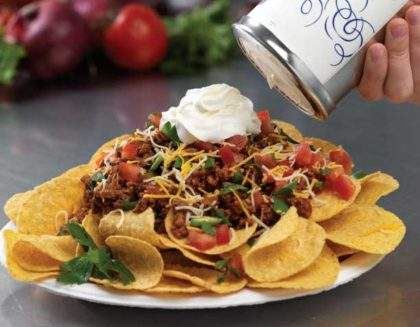

As part of their patented Quikspread container system, Huhtamaki supplies specially engineered dispenser plugs for some of the world’s most well-known foodservice outlets. The G3 plug was designed by Huhtamaki as a hybrid version to improve both filling line performance and precise portion control of sauces such as mayonnaise and tartare sauce.

Manufactured by injection moulding, this unique plug is technically challenging as it demands consistent process control. In particular, the accurate moulding is critical as it enhances the dispensing performance of the container system thereby reducing product wastage.

Huhtamaki first approached Robinson as they were keen to find a UK-based partner who could meet their high standards for quality and service.

An industrial-scale injection moulding solution delivered

Robinson is known for investing upfront in specific equipment and capacity for their customers. Huhtamaki was no exception.

A dedicated manufacturing cell is located at our Stanton Hill plant in Sutton-in-Ashfield, Nottinghamshire. It is equipped with a multi-cavity tool, high-speed press and special handling robotics. It has been instrumental in enabling the continued expansion of Huhtamaki’s Quikspread system throughout the UK’s most popular foodservice outlets.

Robinson is proud to be the first company in the world to manufacture the plug on an industrial scale.

The project involved close cooperation with Huhtamaki’s Technical Department in Kansas, USA, and involved a rigorous pilot tooling stage to enable market validation by both the filler and brand owner.

“Our reasons for working with Robinson were primarily two-fold. We needed a supplier who not only offered reliability and quality but who could work at pace to meet our growth aspirations for the UK market. We’ve certainly achieved both by partnering with Robinson. They invested in state-of-the-art tooling and equipment for this project showing a long-term commitment to supporting our ambitions. ”

Huhtamaki’s Product Manager

.jpg)