If this is your company, CONTACT US to activate Packbase™ software to build your portal.

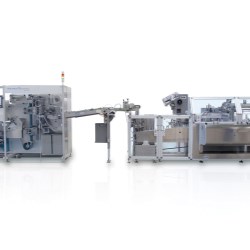

Romaco and Huhtamaki present the first recyclable strip packaging for pharmaceutical solids. An HM 1-230 heat-sealing machine from Romaco Siebler is used to manufacture the Push Packs.

Pharmaceutical manufacturer Romaco Siebler and foil specialist Huhtamaki are about to launch the market’s first ever recyclable unit dose packaging for solid pharmaceutical products. The newest Push Pack model is made from recyclable polyolefin laminate. The unique structure of the strip packaging foil enables it to be recycled back into the material loop.

More than 90 percent of the components which are used to make the packaging belong to the same material class (PE and PP). The result is a primary packaging recycling rate of better than 70 percent. Huhtamaki’s innovative foil is processed into four-side sealed strips with a push-through function using Romaco Siebler’s proven heat-sealing technology. Romaco and Huhtamaki developed the recyclable Push Packs as a joint step towards more sustainable pharmaceutical packaging.

Push Packs save material and costs

As far as the eco-balance is concerned, the packaging forms in the Push Pack product family have inherent advantages over conventional blister packs. This is due to the significantly lower material consumption, especially in direct comparison with Al/Al blisters. The Push Pack foil exhibits the same barrier properties as blister foil but is much thinner and lighter.

The heat-sealing machines in Romaco Siebler’s HM 1 series process this ultra-thin primary packaging foil into air, light and moisture-tight push-through strips. The QuickSeal technology was developed by Siebler specifically for handling laminates with an aluminium foil thickness of between 9 µm and 25 µm. Push Packs are consequently less than half the weight of Al/Al blisters. The material saving is additionally reflected in the costs: Push Packs are up to 60 percent cheaper than Al/Al blisters.

PVC-free

Regardless of whether the standard, barrier or eco version of the Push Packs is chosen, all packaging forms are made from PVC-free material. Since the relatively small cavities in the Push Packs also mean smaller air pockets, the medicines have a longer shelf life. Romaco can supply the push-through sealed strips in various geometries and designs on request. All Push Packs have a large surface that can be printed on both sides.

Siebler heat-sealing machines pack between 800 and 7000 tablets per minute depending on requirements.

.jpg)