If this is your company, CONTACT US to activate Packbase™ software to build your portal.

One of the first things you need to consider is the type of ice cream packaging you’re working with as it’s closely related to a key challenge of preserving its sensory attributes and providing protection during transportation. That brings us to factors such as temperature control, packaging design, and sustainability which need to be taken into consideration. Experienced packaging suppliers are aware of many types packaging existing in the market, however it’s cardboard that‘s become popular in recent years.

Maintaining the proper temperature throughout the cold chain is crucial. Ice cream should be packed and transported at ultra-low temperatures, typically between -20°C and -30°C (-4°F to -22°F), to prevent melting and preserve its creamy texture. Specialized packaging materials like insulated containers or dry ice are utilized to maintain the required temperature range during storage and transport.

Packaging material and design play a significant role in protecting the product. Sturdy containers made from materials such as high-quality paperboard or durable plastics are used to withstand handling and prevent physical damage. Airtight seals and moisture-resistant barriers are essential to prevent the formation of ice crystals and maintain the smoothness of the ice cream.

Furthermore, aesthetics and information are vital aspects of ice cream packaging. Vibrant colors, captivating imagery, and clear labeling conveying flavor profiles and nutritional information enhance consumer appeal and facilitate informed choices.

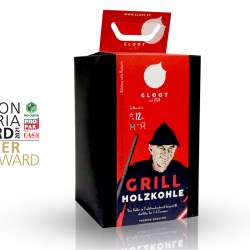

As sustainability becomes increasingly important, manufacturers are exploring eco-friendly packaging solutions. Biodegradable materials and packaging made from recycled and renewable resources are being considered to minimize environmental impact and so it’s cardboard packaging which has recently gained popularity. Advantages like cost-efficiency, customizability, and eco-friendliness are pushing its competitors into the background.

Cardbox Packaging is an experienced ice cream cup producer, offering wide range of cup sizes starting at 100 ml to 550 ml. For sizes of 100 ml to 250 ml there is also the popular option to put the wooden spoon in the lid, resulting in ice cream to go. Thanks to the wide experience of the ice cream packaging industry, Cardbox Packaging successfully developed square box packaging for ice cream, in order to get unusual shape and to impress at first sight.

„My packaging solution, developed together with graphic designer Michael Schumer and the team from Cardbox Packaging, reflects the demand for sustainable individuality. With the corner in the name, a square solution was obvious.“ Michael Reisecker describes the concept of square ice cream, creating the whole corporate identity of small regional ice cream manufacturer Reiseckers Eismanufaktur. „The cubes are folded in cooperation with Lebenshilfe. The inlaid wooden spatulas are from a local carpenter. The disposable paper packaging was important to me because the CO2 footprint is lower than, for example, glass solutions. The hand-sealing is a symbol of the craft of making ice cream. Organic, regional and seasonal are elementarily important to me and they are also visually embodied in the organic cubes,“ he concludes.

The production is always customized to individual customers. Depending on requirements, a final packaging is practical and sustainable at the same time.

photo: Reiseckers Eismanufaktur

Standard portfolio of ice cream cups consisted of six size options from 480 ml to 120 ml. Due to a strong customer demand for lower costs, smaller sizes became a popular product on shelves and so the new 100 ml size cups has been developed. For all sizes ranging from 100 ml to 250 ml there is also the favourite option to put the wooden spoon in the lid.

„The main advantage is the ability to offer lower entry level for consumers and keeping the proven concept of ice cream packaging to go,“ explains Hans Pridal, sales director of Cardbox Packaging, Sustainable Products division. He admits that current demand for low-cost products was the main purpose of this release.

The entire production in Pinkafeld, including cups department, comes under strict food safety rules, hygiene regulations, and quality control processes to ensure it can withstand even very cold temperatures keeping the ice cream fresh. This means choosing the right raw materials, including coatings. Besides the standard PE coating, there are sustainable options too. For example, the bio PLA coating which is made of renewable resources is completely recyclable with the product.

Klaus Hockl, managing director of Cardbox Packaging Holding GmbH, concludes: „Thanks to our in-house development centre and strong partnership with experienced buisness partners, there are new barrier coating technologies in development which allows our cups to expand also to other food sectors.“

About Cardbox Packaging

Cardbox Packaging is an international producer of high-quality and sophisticated cardboard packaging in the luxury and branded goods sector, with a particular emphasis on the food industry. Maintaining the highest quality standards and ensuring customer satisfaction are its top priority. Cardbox Packaging benefits from its lean structure with locations in Austria (Wolfsberg and Pinkafeld), the Czech Republic (Zádveřice), Serbia (Belgrade), and the United States (Pittston, PA). It is an attractive, expert partner for the European and American markets, particularly in the confectionery, food, cosmetics, and healthcare sectors.

Interested already? Contact us directly to get your price offer of 100 ml cups & lids!

doris.hofer@cardbox-packaging.com

Zádveřice, March 2023. In the past, the graphic part at Cardbox Packaging was focusing on the adaptation of carton segment data for customers in the dairy industry only. Due to growing volume of orders, more workforce was demanded, which led to the new investments in various processes helping to improve external collaboration as well as internal system. In order to market the acquired skills effectively, the portfolio of the offered services to different brand owners has been extended. Among others, the new Unit is now offering wide range of 3D visualisations or creative works.

Forming the Unit has started in the second half of 2022, consisting of 7 graphic designers today. All digital related operations now belongs under the Digital Business Unit which brings advantages primarily in a form of process unification. More than ever we are allowed to claim we pack from an idea to realization; including value added services.

DATA MANAGEMENT

Every process starts with our customized data management software. Since the beginning of the packaging life cycle, data are stored and backed up online within our internal system. This customized tool enables customers to manage their data online at any time at any part of the process which makes the whole cooperation transparent and trackable, resulting in 0% unapproved artwork complaints.

ADVANCED PROCESSING

At the beginning of the packaging process, it is desirable to create a packaging construction with fitted graphic design; from a scratch, or adjust the completed artwork to be printed. Any packaging design trend could be part of your product and any artwork can be ready to print up to 48 hours.

Long-lasting experience with warping is our significant competitive advantage. It ensures faultless fitting of an artwork for rounded products, such as cups, bottles or bowls. The additional prepress actions include also complete color management, image adjustments, trapping, bleed or EAN validation.

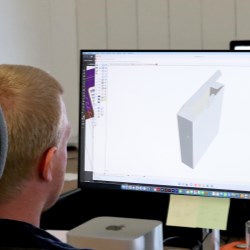

3D VISUALIZATIONS

Launching a new product or changing an existing product carries a number of risks, especially investment risks. However, these risks can be easily mitigated by 3D visualisation of your final product itself or as a store/shelf visualization. The desired product can thus be easily evaluated before production. A realistic mock-up of your packaging is now a standard part of our graphic design services.

SUSTAINABLE APPROACH

The implemented control processes and mechanisms guarantee error-free data processing, which is the key to the entire job. As we enable all services related to the production of the packaging, you do not need another supplier for the successful execution of the order and all steps are properly interlinked. As a result, there is no waste of incorrectly printed material.

About Cardbox Packaging

Cardbox Packaging is an international producer of high-quality and sophisticated cardboard packaging in the luxury and branded goods sector, with a particular emphasis on the food industry. Maintaining the highest quality standards and ensuring customer satisfaction are its top priority. Cardbox Packaging benefits from its lean structure with locations in Austria (Wolfsberg and Pinkafeld), the Czech Republic (Zádveřice), Serbia (Belgrade), and the United States (Pittston, PA). It is an attractive, expert partner for the European and American markets, particularly in the confectionery, food, cosmetics, and healthcare sectors.

After the previous years of growth, the need for a physical expansion was critical. For the biggest project of the site so far, Architekt DI Heimo Wieser & Partner Ziviltechniker KG, Spielberg, was chosen to take control of the processes associated with the premises constructions. The expansion will primarily increase the surface for production and warehouse premises.

Supported by Heidelberger Druckmaschinen AG, the machinery park in Wolfsberg will contain the new printing line Heidelberg XL 1067LYYLX (7c+2v) and two die-cutting Mastermatrix machines. With the new technological investments and the high grade of automatisation Cardbox Packaging Austria will be perfectly prepared for future growth.

Following Wolfsberg site, the Pinkafeld plant is planning to reorganize its premises layout as well. Cardbox Packaging Wolfsberg shall start the new operation in Q4 2022.

“Thanks to the investment with respect to the Cardbox Packaging Group, the Wolfsberg site will be able to strengthen its focus on special packaging solutions supporting our customers with top innovative equipement and dedicated workflows strongly meeting the future market demand. At the same time, implementing a very unique off-line coating line the site will be expanded to become a breaking new ground hub of expertise for sustainable barrier solutions,” explains Roland Schöberl, Managing Director of Cardbox Packaging Holding. The barrier coatings have become one of the group’s key specializations, becoming successfull in the European packaging industry. “We strongly believe our decision will turn the investment into the new vital asset within the group, supporting the overall business growth,“ concludes Klaus Hockl also Managing Director of Cardbox Packaging Holding.

The Cardbox Packaging Group, with sites in Austria, Serbia, Czechia and the USA, has been active in Carinthia since 2011, employing 60 of its almost 250 employees at this location. Alongside with the plant expansion, the workforce growth is being planned too. A number of global branded companies consider Cardbox Packaging a valuable partner in the development and production of high-quality and sustainable packaging solutions. The continuously rising annual turnover of the group is expected to reach €50mil in 2022.