If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Linx Printing Technologies has added two new variants – Linx Brilliant white 1316 and Linx Blue pigmented 1053 - to its extensive range of pigmented inks, which deliver vivid contrasted codes across a wide variety of substrates, including rubber, plastics and metals.

Linx Brilliant white 1316 can be used with Linx’s Midi and Ultima printheads, offering a smaller nozzle size to produce small but still very bright and readable codes, with excellent adhesion on many substrates, including rubber and most plastics. It produces a highly removal-resistant code and is ideal for applications such as cables, pipes and tubes, electronic and computer components, rubber and plastic mouldings and extrusions, and also perfumes and other alcohol-rich products.

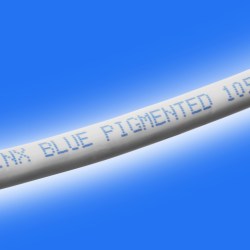

Developed for the Midi plus and Ultima plus printheads, Linx Blue pigmented 1053 ink’s excellent opacity ensures clear codes on both light and dark substrates, and provides excellent resistance to alkali, acid, water, alcohol, petrol and cutting fluid. Its quick drying time means it can be used on fast-moving production lines or where products are handled soon after printing. It is suitable for many different materials, including rubber and most plastics, offering a reliable coding solution for cable extrusions, parts marking and high-contrast packaging applications.

Both inks provide a shelf life of nine months, longer than many competitor pigmented inks, which helps companies to carry out effective stock management. They offer good splash and rub resistance and their excellent heat and light fastness means they are perfect for coding onto products which are stored or used outside. The inks resist migration through printed surfaces and will not transfer onto adjacent surfaces.

Linx Brilliant white 1316 and Linx Blue pigmented 1053 inks have been developed for the market-leading Linx 7900 Spectrum CIJ printer, which is specifically designed for pigmented inks and offers ease of use and reliable, best-in-class performance.