Public

MMC Packaging Catalog

MMC Packaging Jobs

MMC Packaging Locations

MMC Packaging News

MMC Packaging Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

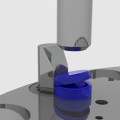

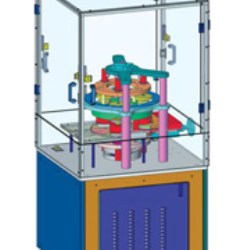

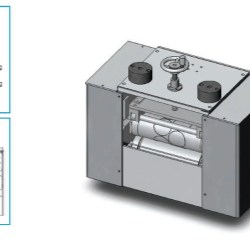

MMC recently collaborated on a project with Husky Injection Molding in order to design, manufacture, and assemble two highly-advanced cap assembly machines. The equipment was specifically designed for the production of two-piece closures, and works at rates of up to 500ppm. Such complexity and precision given to the cap is unparalleled.

Project management efforts and collaboration from both MMC Packaging and Husky Injection Molding made for a seamless partnership, just as one would expect from leaders in their fields. MMC Packaging and Husky are both dynamic Canadian companies, well-respected as influencers within the industry.

In addition, MMC Packaging will be presenting at the first-of-its-kind Husky World Tour in June in Bolton, Ontario (Canada). For more information, click here .

MMC is powered by an experienced engineering team that designs reliable and durable machines - those that can withstand the harshest conditions. Throughout the lifecycle of the equipment, MMC Customer Service is always on hand to assist and offer services that will continuously enhance the efficiency of the equipment. For more information contact MMC .