Public

LageenTubes Certificates

LageenTubes Image Gallery

LageenTubes Locations

LageenTubes News

LageenTubes Shows

LageenTubes Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

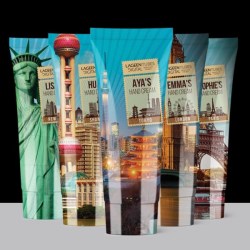

LageenTubes is your development partner and supplier for custom plastic and aluminum packaging solutions. We operate as a trusted extension of your own product development, marketing and operations staff, with the same commitment to success.

LageenTubes works especially well when your tube specifications call for innovative solutions. Together we design a visionary concept of the tube and make it a reality – providing you with the best solutions for your needs.

In the fast-moving consumer goods industries, time-to-market is a key success factor. We at Lageentubes understand that. That is why we created an agile development process for our customers, enabling them to launch their product in a dream package when and where they want.

The Fast Lane Development Process™ (FLDP™) consists of 7 steps for turning your dream packaging into a reality:

- Understand the industry’s unique trends, needs and specifications.

- Conceptualize a competitive and differentiated tube concept.

- Come up with an engaging custom design.

- Determine manufacturing feasibility – both look and functionality.

- Create a 3-D prototype.

- Go to full-scale production.

- Delivery quality tubes in a timely manner.

LageenTubes' comprehensive capabilities, accumulated over 50 years as an OEM expert, empower us to bring your challenging ideas for extraordinary tubes to life. We offer you a winning combination of integrated capabilities, the most advanced production processes and decoration technologies, decades of experience and extensive expertise, and a history of trusted partnering with leading global companies in diverse industries from around the world.

Driven by our strong focus on customer satisfaction, our team is committed to meeting the highest standards of quality, functionality, and reliability throughout the entire development process through to full-scale production and delivery.

Creative Approach

We want our customers to lead the agenda in their marketplace. Therefore, we established a network of multi-dimensional marketing, industrial design and material engineering experts who work together to conceptualize breaking through ideas. We are continuously engaged with our customers, providing them with new packaging concepts, improved materials and unique caps for easier and more convenient usage.

LageenTubes’ printing experts challenge themselves to create new decoration textures, colors, effects and integrated visibility impacts, all for the purpose of introducing novelty products for various applications and industries and supporting our clients’ brands.

The technology team at LageenTubes is constantly engaged with our strategic customers in research and studies regarding barrier limitations, product resistivity, product migration, dispensing mechanisms and extended shelf-life possibilities.