If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Linx Printing Technologies is making laser coding more accessible than ever with the launch of the Linx SL1, an entry-level solution that enables more food and beverage companies to achieve a high quality code which adds value to their packaging.

The Linx SL1 laser coder has the speed, reliability, ease of use and low cost of ownership synonymous with the Linx scribing laser range, but is tailored particularly to customers who may have thought laser's benefits were out of reach.

The Linx SL1 delivers class-leading coding speeds thanks to the use of lightweight and ultra-fast mirrors. It offers 20% more power than other products in its class, but at the same time uses much less laser energy in the coding process, which together with its robust stainless steel design further enhances its reliability and longevity.

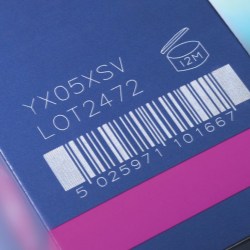

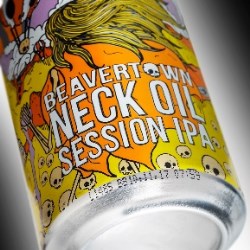

The new laser coder also offers greater coding versatility than comparable models, with the ability to produce multiple lines of text and logos in one message, as well as machine readable codes such as QR and Data Matrix codes. This versatility enables the Linx SL1 to apply decorative codes capable of matching the look and feel of the packaging design.

Another benefit is the coder's size. One of the most compact one-box laser solutions on the market, and weighing only 12.5kg, it is simple to position on line and fits easily into tight spaces, coding in any orientation.

Set up and code changes are easy, thanks to the exclusive LinxDraw® software which provides intuitive operation, secure message creation on- and off-line and tamper-proof coding.

The Linx SL1 offers all the established benefits of laser coding. The technology uses no fluids and consumables, reducing running costs, eliminating mess and spills, and removing the need to store inks and solvents. No production time is lost to cleaning printheads and there are no unknown variable costs. Fewer moving parts mean less maintenance and no time-consuming start-up and power-down procedures – a real advantage on lines that don't run round the clock.

Lasers also create a permanent mark on a product, which can't be rubbed off, making it the ideal solution for traceability and anti-counterfeiting.

Laser printers deliver high quality, permanent codes on almost any substrate, although the Linx SL1 is particularly suited for coding on to paper and card, as well as plastic or glass on slow-to-medium production line speeds.

Matt Eastham, Linx laser product manager, says:

"The affordable Linx SL1 brings the trusted benefits of the established Linx laser range within the grasp of a whole new range of potential customers. Simple, flexible and economical, it opens up a new world of coding possibilities to those who may not previously have considered laser as an affordable option.