Public

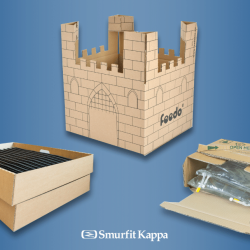

Smurfit Kappa Catalog

Smurfit Kappa Gallery

Smurfit Kappa Locations

Smurfit Kappa News

Smurfit Kappa Videos

Subsidiaries

Saxon Packaging

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Smurfit Kappa Roermond Paper Mill’s integrated steam system has been held up as a shining example of sustainability for reducing its CO2 footprint by a further 3% in 2018. The steam project is part of an ongoing intensive energy and CO2 reduction programme at the mill which has achieved a specific CO2 emission reduction of 23% since 2005.

The Roermond Paper Mill runs three paper machines to produce recycled paper for corrugated packaging. Under the previous configuration, the residual steam of two of the machines was only partially reused. As part of the mill’s ongoing project to reduce carbon emissions, it integrated the steam systems from all three paper machines by incorporating a sophisticated control system. The machines operate at different speeds using a variety of paper weights which added to the complexity of the task.

Speaking about the innovative steam system, Wim Janssen, Energy and Production Technologist at the mill, said: “We started by carrying out an in-depth analysis of processes to figure out a way to reuse excess steam from two of the machines in the third machine. This has reduced the mill’s gas consumption and slashed the 2018 CO2 emissions by an impressive 4,500 tonnes.”

Wouter Lap, MD of the Roermond Paper Mill, added: “What started as a pilot project has resulted in a modification of the mill’s steam system. At Smurfit Kappa we believe that the best ideas come from collaboration, creativity and being prepared to view our processes from different perspectives.

“This is a further example of how the Roermond Paper Mill is leading the paper industry in sustainable energy consumption.”

The steam integration project was showcased at the European Parliament as part of the Confederation of European Paper Industries’ (CEPI) ‘To our roots and beyond - RE-INVEST 2050’ scheme which aims to advance low-carbon innovation in the forest fibre and paper industry in Europe.

.JPG)

.jpg)