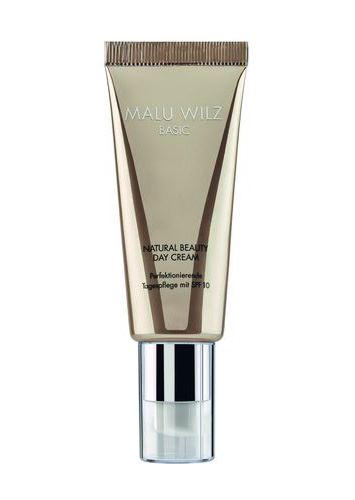

Malu Wilz has just launched its Natural Beauty Day Cream.

Malu Wilz packages its products in jars and tubes. For its Natural Beauty Day Cream, the product's management wanted an attractive tube variant that spanned beauty care and decorative cosmetics. They chose Neopac's Polyfoil®-Evolux, a glossy finished tube with an Airless Pump.

The capsules of pigment pearls in the cream break open when applied to the skin and complement almost every skin tone, giving a very natural, even complexion. Thus, a hygenic solution was imperative for the cream to maintain functionality.

Tessa Webinger, product manager at MALU WILZ, believes that the airless function is the most hygenic solution for her customers as it prevents air and bacteria from reaching the contents and so offers safe protection. She is also impressed with the finish:

"The high-gloss tube really appealed to us visually and perfectly fits our requirements for elegant packaging." The greatest challenge of the product was timing: "Usually, we are looking for short lead times so that we can implement the latest trends in the cosmetics market as quickly as possible. Precise coordination is required to ensure all components are available on time. And we have achieved it together."

Commenting on the working relationship with Neopac she says:

"Neopac has been a reliable partner providing packaging of the highest quality, so it was the right decision to choose Neopac for our new tube. We expect the highest product quality, reliability, advice on technical matters and product innovation from a packaging manufacturer."

Malu Wilz Beauté

Malu Wilz Beauté is part of the ArtDeco Cosmetic Group and sells its cosmetics products in Europe, Asia, Canada and the Middle East. The product Natural Beauty Day Cream is available from beauticians, partner institutions and the online shop.

.jpg)