Public

Gerresheimer Brochures

Gerresheimer Gallery

Gerresheimer Locations

Gerresheimer News

Gerresheimer Product Catalog

Gerresheimer Publications "Update"

Gerresheimer Videos

Subsidiaries

Sensile Medical

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

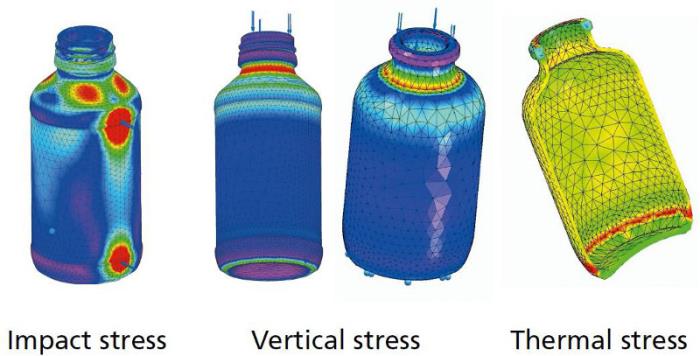

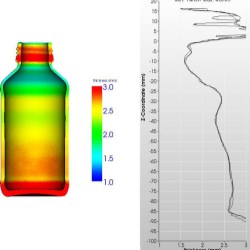

Glass production begins with engineering the mould. The more accurately the moulds are designed and made, the greater the quality of the bottle. A perfect and even distribution of glass is the key to success when it comes to ensuring the robustness and sustainability of these highly sensitive products. Gerresheimer employs innovative simulation software for this purpose. This adjusts the production parameters using CFD (computational fluid dynamics) as a basis, which improves the products and reduces development time.

“Our customers are demanding sustainable and therefore lightweight yet stable products,” says Philipp Amrhein, Manager of New Product Development & Mould Design at Gerresheimer in Lohr.

To ensure it is in the position to meet these requirements, the company is using simulation software developed to calculate sturdiness and simulate the production process for moulded glass. The moulding production process and design of the moulds are being optimized, taking account of all the chemical and physical parameters of the glass. CFD simulations are also being used to optimize the respective process, which reduces stresses in the glass container and is an effective way to improve the quality of the production process.

Cutting development time by up to 70 percent

While getting a stable production process used to require lengthy empirical testing, this can now be achieved in just a few minutes using computer-based simulation software, more or less at the touch of a button. The results are then immediately transferred directly to the three-dimensional CAD software for mould design via interfaces and used directly by the mould-processing machines to create mould tools. The simulation software also reduces development time by up to 70 percent.

Detecting weaknesses faster

The well-known finite element analysis (FEA) method is used to determine which stresses arising from the production requirements work on the glass containers. These results can be used to prevent weaknesses even before the items have been sketched out. The computer-based simulation of the moulding process and the product requirements from day-to-day mould design are now part and parcel of operations. As an element of Gerresheimer’s continuous improvement process, it is essential.

At CPhI Worldwide in Frankfurt from November 5 to 7, Gerresheimer will be showcasing a wide range of pharmaceutical glass containers for solid and liquid drugs at booth 111B10.

.jpg)

.jpg)

.jpg)

.jpg)