Public

Gerresheimer Brochures

Gerresheimer Gallery

Gerresheimer Locations

Gerresheimer News

Gerresheimer Product Catalog

Gerresheimer Publications "Update"

Gerresheimer Videos

Subsidiaries

Sensile Medical

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Gerresheimer manufactures a comprehensive range of glass and plastic pharmaceutical primary packaging products like syringes (glass or plastics) and insulin cartridges and drug delivery systems, including auto-injectors, asthma inhalers and insulin pens, for many reputed companies in the pharmaceutical industry. At Compamed 2015 from November 16 to 19 the company will be showcasing its products and services on Stand G31 in Hall 8b.

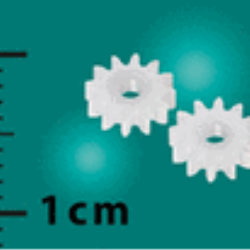

Miniaturization – the trend in medical engineering

Medical device components are gettingcotinuously smaller as requirements of precision increase. There is no binding definition on what constitutes a micro injection molded part, but Gerresheimers' definition is a part with any single dimension of less than 1 mm, a weight of less than 0.3 g and a tolerance of less than 30µm. Conventional injection molding isn’t suitable for theproduction of these miniature parts, to a great extent because a reduction in a component’s length of 50 percent means exponential changes to other properties such as surface area, volume and thermal conductivity. Gerresheimer has special micro injection molding systems that can manufacture extremely small parts precisely and cost effectively. Micro injection molding is associated with challenges relating to tool engineering, injection molding technology and measuring technology. The necessary technology is already available in the market and Gerresheimer is collaborating closely with a network of partners in science and industry to extend their micro injection molding knowledge base.

Mold engineering – for reproducible high precision mold inserts

Extremely precise molds are indispensable to manufacturing top quality micro injection molded parts. For example, if the component‘s tolerance is less than 30µm, the mold tolerance has to be less than 10µm. That’s why Gerresheimers' engineers use special machinery designed for this specific purpose.

Injection molding solutions for extremely small volumes

Conventional injection molding machines aren’tsuitable for the small shot volumes involved in micro injection molding. Long holding times in the plasticizing unit and in the tool’s hot runner system can result in material shrinkage. Also, it is difficult to achieve the necessary precision and reproducibility of the screw’s forward movement during the injection phase, and feeding accuracy is more important due to the back flow check valve.

Gerresheimer overcomes these challenges in two ways. With multi-cavity molds and optimized injection molding machines with special screws and back flow. The advantages of production with suitably optimized standard injection molding machines is particularly evident when large quantities are manufactured. Gerresheimer uses multi-cavity molds in all-electric standard injection molding machines with modified plasticizer units for micro injection molding.

Measuring technology for validation and process control

Gerresheimer has a computed tomography system at their Technical Competence Center in Wackerdorf (Germany). The company uses a special technique to measure micro injection molded parts which securely fixes even the tiniest of objects in place during the measurement and makes it possible to precisely map the difference in density between the object and the supporting structure. False color plots then permit the fast analysis of the measurement results.

.jpg)

.jpg)

.jpg)

.jpg)