If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Ishida’s ability to devise universally available solutions for specific products and applications has been underlined by the introduction of a new multihead weigher into its Sector Solutions range. The CCW-RV-216W-1S-20-SS-STK1 is a standard model designed to handle the particular challenges of stick snack products at high speeds - up to 120 packs per minute - with no loss of accuracy or product quality.

Pretzel sticks - in salted, plain, seeded and filled varieties - are a hugely popular snack in countries such as Germany, Turkey and the Middle East and are a growing market in many other areas. Their fragile and dusty nature makes them particularly difficult to pack in an automated weighing system.

The Ishida stick weigher has been designed for gentle handling of the fragile stick snacks to minimise the potential for breakages. It ensures optimum flow of the sticks, with reduced angles throughout, a low-profile inlet chute, convex dispersion table, and waterfall ends for smoother transition of the long products into the pool hoppers. Special electrostatic polished contact parts reduce dust build up throughout the weighing process.

To enable maximum flexibility in handling different pack sizes, from 35g to 250g, the weigher is also supplied with special hopper inserts. These align the sticks and keep them upright, ready for a clean transfer.

Following initial weighing, each batch of sticks used in the combination is held in a special shutter hopper mid-way down the discharge chute to ensure they remain correctly aligned, ready for discharge into the bag. The correct combination of product is then transferred via a high-speed discharge chute which also incorporates an inner guide insert to maintain alignment down to the next section. To reach the pack, the sticks pass through a pneumatically-driven triple Iris type timing hopper that settles the product as it passes through each stage of the iris. At the second stage it is passed through an oscillating device before a cutting device is used at the third stage to remove the top of any remaining misaligned sticks. Any last sticks cut then stay on the top of the bundle to ensure the correct target weight is not compromised in the final pack.

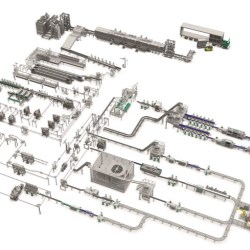

The Ishida stick weigher is particularly suitable for the packing of product into bags, including pillow and block bottom varieties, but it has also been successfully combined with other downstream equipment, for example for discharge into trays. It is available as a stand-alone weigher or can be supplied with an Ishida snacks bagmaker for a fully-integrated solution. In addition, Ishida can devise and install a complete line from the moment the sticks exit the oven, with special non-vibratory belt feeders that provide gentle handling and ensure the correct length and alignment of the sticks as they enter the weigher.

As part of Ishida’s most advanced RV series, the new stick weigher also incorporates a number of features that deliver the highest levels of speed and accuracy. Advanced software, improved digital filtering, refined anti-floor vibration, faster processing speeds, more precise feeder control and enhanced average weight control all combine to deliver a market-leading performance to increase packed product yields. A robust construction ensures long-term reliability, and an easily accessible design, including a slide-out frame for the Iris timing hoppers, provides ease of access for servicing and cleaning for maximum uptime.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)