If this is your company, CONTACT US to activate Packbase™ software to build your portal.

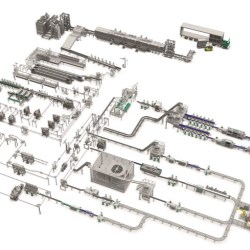

Reliability, flexibility and ease of use are some of the main reasons behind the selection of Ishida weighing technology for the fast and accurate packing of bags of mixed salads at Primaflor, one of Spain’s leading fresh produce growers.

The latest model at the company’s factory in Las Canalejas, near Amería in Andalusia, a 14 head 5 litre CCW-RV waterproof salad model from Ishida’s Sector Solutions range, is the 15th Ishida multihead weigher to be installed by Primaflor, with 12 now in operation at the Las Canalejas factory and another three at its factory in León in northern Spain.

The weighers have been specifically designed to handle the challenging characteristics of many salad products, such as baby leaves which are prone to tangle together and be difficult to move efficiently throughout the weighing process. A steep-angled inlet chute provides an even distribution of product at the top of the weigher, while both the amplitude and frequency of the vibratory system can be adjusted to achieve the maximum power possible to maintain a consistent flow of product to the weigh hoppers. Embossed surfaces help to prevent product sticking together and double opening hopper gates ensure a clean transfer from pool to weigh hoppers.

Equally important, the top of the range RV series weighers deliver unsurpassed accuracy, thanks to the unique triple combination calculation software that can calculate three optimal weight combinations, double check them and then select the one nearest to the target weight - all in a single cycle. This minimises error discharges, increasing efficiency, while also enhancing weighing accuracy and consistency.

Primaflor produces a staggering 2,000 different lines for both its own brand products and private label and the similar specification of the Ishida weighers at the Las Canalejas factory is therefore very important, giving the company great flexibility in being able to respond quickly to changing customer requirements and allocate machines accordingly. Similarly, the weighers’ ease of set up is also vital in ensuring fast changeovers and was one of the main reasons that the company initially selected Ishida for its weighing requirements.

“When we first tested multihead weighing technology for our salad products, we tried a different supplier, but that weigher was not easy to operate and often required an engineer’s intervention to help with various features,” explains Manuel Santa Cecilia, Primaflor’s Operations Director.

“By comparison, the Ishida weighers are simple to set up and the remote control touch screen is very intuitive – if you can use a smart phone, you can use this screen. This is particularly important as we have operators from many different countries, so the multi-lingual touchscreen helps to overcome any language barriers.”

The fast, efficient and reliable performance of the Ishida weighers are the key reasons why Primaflor has continued to specify these models. Such consistent operation is essential for a factory that handles around 60 tons of product every day. The weighers are packing a variety of bag sizes, from 50g to 2kg for both the retail and foodservice sectors. Manuel Santa Cecilia says overall accuracy is excellent while speeds vary from 30 to 75 packs per minute depending on the pack size and the flow of the product through the weigher.

The machines are in operation for two shifts Monday to Saturday. Their hygienic design and durable construction enable fast cleaning by compressed air during product changeovers, while the weighers receive a comprehensive washdown at the end of each day. Hoppers can be easily removed without tools and placed on a special ‘wash down wall’ for cleaning.

The Ishida weighers have been supplied by Ishida’s longstanding Spanish agent CIMA.

“The reliability of the machines is critical to maintaining efficient production, and we receive excellent technical support from CIMA whenever we need it,” concludes Manuel Santa Cecilia.

Primaflor was established by three families to offer quality naturally fresh foods for a healthy and active life, and today farms 6,400 hectares of crops. The company supplies a range of products including fresh fruit and vegetables, iceberg lettuce, baby leaves and Romaine lettuce, and prepared salads, along with complementary items such as salad dressings.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)