If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Solutions to help businesses deal successfully with some of the key challenges currently facing the global food industry will be demonstrated on the Ishida stand at this year’s Scanpack.

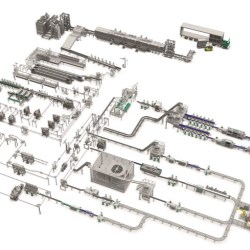

Companies are having to tackle the rising costs of material and energy, along with labour and skills shortages, while maintaining operational efficiency, including minimising waste and giveaway, and ensuring consistent product quality and safety. The range of Ishida equipment on display will show how automation can help to make a real difference in all areas of the packing line. Ishida experts will be on the stand to discuss specific customer requirements and outline the company's wider expertise in the design and installation of fully integrated processing and packing lines.

Highlights include two specialist multihead weighers and Ishida’s recently introduced IX-G2-F X-ray inspection system, which have been developed to meet the specific challenges of fresh protein applications.

The CCW-RV-214-SF, Ishida’s high performance screw feeder weigher, has enabled the fully automated handling of sticky fresh products. The technology uses rotating screws to provide a powerful, controlled and fully automatic product feed to the weigh hoppers. This significantly reduces giveaway and automates the weighing process for difficult to handle products. Speeds are further maximised thanks to the RV’s unique triple combination calculation software. In a single cycle, this calculates three optimal weight combinations, double checks them and selects the one nearest to the target weight.

The Ishida CCW-R2-106B Fresh Food Weigher (FFW) provides an alternative semi-automatic solution for handling very sticky fresh and bruise-sensitive products and is particularly suitable for factories with height limitations. The weigher can receive product from a conveyor belt to the top of the weigher, where one or two operators evenly distribute it via belt feeders to the weigh hoppers. This helps to maximise the speed and efficiency of the weighing process. The FFW’s ergonomic layout makes it easy to spread out products on the feeder table and the belt feeders facilitate a precise and consistent product feed to the hoppers. Features such as scraper hopper gates, ribbed surfaces and scraper gates on the collection belt conveyors minimise product sticking.

The Ishida IX-G2-F dual energy X-ray inspection system incorporates a new line sensor that provides a high-quality X-ray image through an enhanced signal to noise ratio. This has an increased capability to detect bone fragments by a factor of four compared with previous X-ray models. It further enhances the ability of the machine to identify foreign bodies, in particular when handling thicker and denser products such as chicken fillets, chicken breasts and a wide range of poultry products where they can often be overlapped or presented with uneven surfaces.

Completing the stand line-up will be two of Ishida’s versatile and high-performance entry-level quality control solutions, the IX-EN-4093S X-ray inspection system working in combination with the DACS-GN-SE checkweigher.

The IX-EN-4093-S combines impressive sensitivity with minimal operating costs. The machine incorporates Ishida’s unique Genetic Algorithm (GA) image processing technology which delivers superior inspection sensitivity. It can reliably detect foreign bodies including steel, aluminium, tin, glass, stones, dense rubber, plastic, bones and shells for unrivalled food safety in a wide range of packaged and unpackaged food products. The X-ray technology can also carry out additional quality checks such as identifying damaged or missing items, weight estimation and counting components.

The DACS-GN-SE-WP offers exceptional performance at an affordable price. Ishida loadcell technology delivers unsurpassed weighing accuracy and consistency while the availability of AFV (Anti Floor Vibration) technology increases accuracy in environments susceptible to floor vibration. In its IP65 certification, the checkweigher is ideal for challenging wet environments and to meet stringent cleaning requirements. The DACS-GN-SE can be fitted with Ishida Retail Reject Confirmation (RRC) to help food manufacturers meet the latest retail codes of practice. It is also available with Ishida’s pioneering Ishida Data Capture System (IDCS II), a powerful software that captures the data from every pack that passes across the checkweigher and generates real-time displays and reports which focus attention on major cost-saving opportunities and improved Overall Equipment Effectiveness (OEE).

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)