If this is your company, CONTACT US to activate Packbase™ software to build your portal.

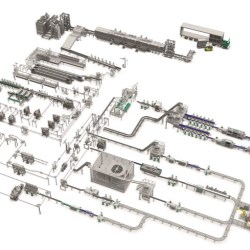

Ishida’s capabilities in the design and installation of complete processing and packing solutions for meat and poultry will be amply demonstrated at VIV Europe, where the company will demonstrate three fully integrated lines encompassing weighing, marination, grading, pick-and-place packing, traysealing, quality inspection and labelling.

A major highlight will be the Marination Line, where fresh chicken pieces will be weighed, marinated and sealed in a custom-built cold room. The line features Ishida’s newly-launched, award-winning Orbicote marination system that delivers marinated products more efficiently and consistently than ever before. It combines Ishida’s proven multihead weighing technology with a specially designed series of 12 mini-drums. Weighing takes place before marination to avoid the waste traditionally associated with this process. Each accurately-weighed portion is channelled into an individual mini-drum where it is tumbled with a set dose of marinade. This ensures that product is thoroughly coated before the contents are cleanly dispatched into a traysealer.

The Orbicote is being demonstrated with Ishida’s pioneering Screw Feeder weighing technology, shown in a 20 head model, which uses rotating corkscrews to provide a powerful, controlled and fully automatic product feed to the hoppers. Marinated pieces are placed into trays and sealed in an Ishida QX-775 Flex tray sealer. This combines a compact design with speeds of up to 20 cycles per minute.

…/

A separate robot grading and traysealing line utilises Ishida’s advanced IX-G2 dual energy X-ray system for the detection of even small bones and bone fragments in meat and poultry. Inspected fillets are packed into trays using the unique RobotGrader, which combines weighing and pick and place technologies to grade products of varying piece weight and place them into a fixed weight pack.

Packs are sealed using Ishida’s top-of-the-range QX-1100-SDL (Split Dual Lane) tray sealer. The SDL model operates each lane independently, enabling food companies to run two separate sealing technologies (such as MAP vs skinpack as shown on the Ishida stand), tray sizes, pack weights, or products, at the same time at different speeds and in only one machine footprint.

At VIV all packs are inspected for leaks in Ishida’s award-winning AirScan, where advanced laser technology is able to detect holes as small as 0.25mm in trays packed in a modified atmosphere. Good MAP packs are then labelled by Ishida’s Weigh Price Labeller while skinpack trays pass through a C-wrap labeller.

The third line features Ishida’s Flexgrader linked to a high speed infeed. The Flexgrader utilises Ishida weighing technology to provide a fast operation with excellent accuracy that grades product to a variety of different requirements. These can be to specified weights, minimum weight or number per pack. The system can also deliver target batching with tolerances and priorities.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)