If this is your company, CONTACT US to activate Packbase™ software to build your portal.

An Ishida packing line solution comprising a multihead weigher, bagmaker and checkweigher has been instrumental in the launch of a new healthy snack from snacks specialist Good Food Products, Poland’s largest manufacturer of rice and corn wafers, crackers and popcorn snacks.

Corn A'petit waffle snacks are produced from corn kernels and are baked with no added fat, preservatives or gluten and with reduced salt, making them a healthy alternative for snack fans. Because the snacks are 45mm in diameter, compared to traditional wafers which are 90mm, Good Food Products was seeking a completely new production line that was able to cope with this specification.

“When we were choosing our line supplier, we did a thorough market research and Ishida turned out to be the optimal choice,” said Łukasz Wawrzyniak, Engineering Department Manager at Good Food. “The quality of the company's machines speaks for itself. We wanted to have the best solution for our new product, which we consider as a breakthrough on the snack market.”

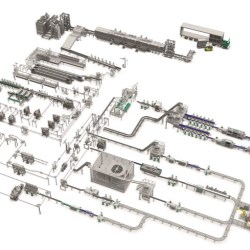

Integrated solution

The integrated Ishida solution features the company’s 14 head CCW-RVE multihead weigher combined with its Inspira bagmaker. The bagged snacks then have a final weight check on Ishida’s DACS-G checkweigher.

Ishida’s patented Pulse Width Modulation (PWM) technology provides greater control of the infeed of the product at the top of the weigher and to the weigh hoppers. Being able to automatically vary both the amplitude, time and frequency of the vibration ensures a steady and consistent flow of product, maintaining speed and efficiency, reducing the danger of overfill in the hoppers.

The weigher delivers excellent weighing accuracy, thanks to its advanced combination calculation software. After the best combination has been calculated, it is double checked to ensure the discharge is as accurate as possible before the portion is released to the bagmaker.

The Ishida Inspira bagmaker features intermittent jaw motion technology for high-performance forming and sealing. Features such as automated film centring, auto-splice film management, automated air-fill technology and other automatic adjustments, help to ensure consistency in production and minimise human error. Dedicated software- and servo-controlled sealing operation, with accurate jaw temperature and jaw pressure, deliver consistent pack quality and significantly reduce downtime.

The DACS-G checkweigher incorporates Ishida’s Anti-Floor Vibration (AFV) technolgy to maximise weighing accuracy in environments susceptible to floor vibration. Special features include Ishida’s Retail Reject Confirmation (RRC) software that checks and confirms that any out-of-spec product or pack has been successfully removed from the line.

Installation and handling

The Ishida installation is operating 24 hours a day, five days a week. Currently, it is handling 60g packs of Corn A’petit at 40 bags per minute,well within its overall top speed of 90 bags per minute for this application and giving Good Food Products the ability to readily implement future capacity increases.

Key to the success of the project was to ensure the complete integration of the packing operation with the earlier baking and flavouring stages of production.

“The installation went flawlessly and during testing everything was working smoothly” said Wawrzyniak.

Corn A'petit is currently available in several different varieties with new flavours continually under development. This means that the Ishida weigher and bagmaker have to be able to deal effectively with changeovers. All contact parts in the CCW-RVE are easily removable without tools for cleaning, while the intuitive 380mm colour touch screen HMI on the Inspira supports rapid film and format changeovers.

“The weekly number of changeovers depends on how many bags of a particular flavour are planned to be produced, with cleaning being carried out after each changeover,” explained Wawrzyniak. “Cleaning and re-assembly takes around 30 minutes.”

Better control and high efficiency

Overall, the installed Ishida line enables Good Food operators to better control the weighing and packing process, helping to maintain throughput and high efficiency during production.

“After a year, I can evaluate that the machines absolutely meet our requirements,” concluded Wawrzyniak. “Ishida's solutions allow us to adapt to even the most demanding product requirements.”

Founded over 30 years ago, Good Food Products’ focus from the outset has been on quality and innovation. Today the company has factories in Tarnowo Podgórne and Skórzewo and employs around 400 people. Good Food was the pioneer in the production of rice and corn wafers, as well as one of the first to develop more healthy eating alternatives. With further investment, the company plans to develop additional varieties of wafer mini snacks, with different raw material bases, such as vegetable and protein.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)