Public

Mecmesin Catalog

Mecmesin Certificates

Mecmesin Documents

Mecmesin Locations

Mecmesin News

Mecmesin Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Specification

The International Society of Beverage Technologists (ISBT) publish voluntary codes of practice for the technical and scientific aspects of soft drinks and beverages. Their packaging guidelines include Sports Closures: Voluntary Standard Performance Specifications and Test Methods; indicating test procedures for the unique push/pull or twist-to-open spout closure design used on mineral water and sports drinks caps.

Two tests apply tensile loads to evaluate the quality and integrity of the closure: Section 2.1 - Bite Test and Section 2.3 - Tension Test. The purpose of the tension test is to measure the strength of the spout and base assembly, which could become a potential choking hazard were it to break too easily. This is a destructive test, in which a constant force of 111 N is applied to the spout for 10 seconds and, if there is no separation of the assembly, further loading is applied until breakage and the peak recorded. The bite test similarly applies a particular force (270 N) for 10 seconds and records whether any damage or breakage occurs.

Solution

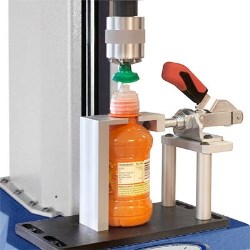

Mecmesin supplied a motorised MultiTest 2.5-i test stand, capable of applying load at the required constant speed of 300 mm/minute and stop travel at the threshold force value, as indicated in the ISBT test standard. Mecmesin offer a fixture which is able to grip the neck of the container, via a lever-operated collar, and a multi-jaw grip which grasps the lip of the spout, or similar feature of any drinks closure. EmperorTM software controls the test stand and generates graphical output of the results and a test report clearly indicating pass/fail status, enabling failures to be detected and the ultimate strength in tension to be recorded for batches of closures.

Mecmesin test equipment is also able to perform similar sports closure performance tests, e.g. measuring the tamper-evident bridge strength on the protective flip-cap.

System

- MultiTest 2.5-i computer-controlled test stand.

- 250 N ILC intelligent loadcell.

- EmperorTM Force testing software.

- Sports Cap Pull-off Fixture with Multi-Jaw Grip (bite clamp).

.jpg)