If this is your company, CONTACT US to activate Packbase™ software to build your portal.

TekniPlex Healthcare, which utilizes advanced materials science expertise to help deliver better patient outcomes debuted the world’s first fully transparent recyclable mid-barrier blister package at Pack Expo in Chicago, showcasing samples of its new materials science breakthrough, which includes barrier protection against moisture.

Recyclable in geographies where the #5 (polypropylene) recycling stream is available, the mid-barrier blisters feature a polyolefin blister film paired with a barrier PP lidding film. This marks the first time a formed blister + lidding combination is certified as recyclable– a significant milestone in the evolving push to make healthcare packaging more sustainable. From a manufacturing standpoint, initial machinability analyses have been positive, with large-scale tests scheduled for the near future.

In addition to debuting the mid-range barrier version at Pack Expo, TekniPlex Healthcare also will premiere a fully recyclable polyester mono-material blister + lidding combination, suitable for products that do not require barrier protection.

“The ability to make transparent barrier blister packages recyclable is a crucial step toward healthcare materials circularity, one in which technical challenges needed to be overcome with extensive research, trials and dedication,” said Chris Qualters, CEO of TekniPlex Healthcare. “We are exceptionally proud to be the first materials science company capable of meeting this longstanding market need, and we look forward to showcasing the new blister packages at Pack Expo.”

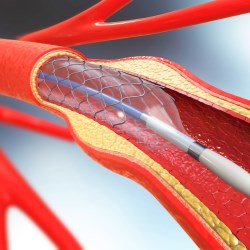

Pack Expo also will mark the launch of TekniPlex Healthcare’s new lower-weight reinforced coated paper for medical device protection. The company’s proprietary coating formulations and application technology result in rolls that can meet demanding performance and sterilization requirements. The reinforced coated papers are suitable for the packaging of a variety of common healthcare items including syringes; tubing such as IVs, catheters and airway filters; gauzes, sponges and bandages; and devices sterilized by EtO and radiation. Notably, the slimmed-down product has already received its first commercial order, from a prominent manufacturer of swab sticks.

Both the fully recyclable blister packages and lower-weight reinforced coated paper exemplify TekniPlex’s “Rethink Responsibly” concept, which commits to continually considering what it means to provide responsible solutions to customers, their consumers, and the planet. The approach reflects the company’s promise to perpetual progress across materials science design innovation, supply chain and operational efficiencies, materials reduction, closed loop manufacturing, and materials diversity, among other areas relevant to sustainability.