If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Developed in collaboration with Alpek Polyester, the film is suitable for a wide array of primary packaging applications, with 30% of its PET polymerized from PCR-origin through chemical recycling.

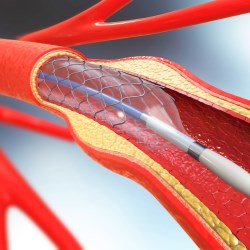

TekniPlex Healthcare, which utilizes advanced materials science expertise to help deliver better patient outcomes, has partnered with petrochemical leader Alpek Polyester to introduce the world’s first pharmaceutical-grade polyethylene terephthalate (PET) blister film containing significant recycled content. Suitable for a wide array of primary packaging applications, 30% of the PET blister film is manufactured using post-consumer recycled (PCR) monomers. When combined with TekniPlex’s polyester lidding, Teknilid® Push, the film plus lidding blister system is also fully recyclable in the polyester recycling stream where recycling infrastructure exists.

To create the next-generation film, post-consumer plastic waste undergoes a depolymerization process via chemical recycling, which reduces it back to monomers. After repolymerization to PET, the result is a recycled resin that is essentially virgin material. Notably, such monomer-level deconstruction and repolymerization is impossible to achieve via traditional mechanical recycling methods. The end product from Alpek’s polymer reactor is a sheet in master reel made according to the melt-to-sheet process.

The benchmark-setting new blister film meets all pharmaceutical requirements for PET as outlined in the European Pharmacopoeia Section 3.1.15, and United States Pharmacopoeia Section 661.1. The achievement was the latest in a longstanding relationship between TekniPlex Healthcare and Alpek Polyester, who frequently collaborate on projects involving the production and slitting of PET film for pharmaceutical and medical applications.

Among other benefits, adopting the new PET blister film with PCR content allows pharma companies to stay ahead of pending sustainability legislation poised to affect packaging in all industries. Perhaps most notably, the EU’s forthcoming Packaging & Packaging Waste Regulation likely will impose recyclability deadlines on all industries and PCR content baselines for various sectors. Similar movements are progressing elsewhere, leading to demand for more sustainable pharmaceutical packaging solutions that do not compromise on material quality, product protection or patient health.

“This is the first time pharmaceutical companies have the option to incorporate a blister pack that is fully recyclable and, at the same time, contains a significant portion of recycled material – all while still meeting stringent pharmaceutical quality standards for product protection and consumer safety,” said Melissa Green, Head of Global Marketing for TekniPlex Healthcare. “We anticipate high demand for this new, more sustainable film, as it meets ever-growing calls for elevated eco-friendliness in packaging across all sectors, including pharma.”

TekniPlex Healthcare will debut the promising new solution at Pharmapack Paris, Stands C48 & C49, January 24-25.