- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

.jpg)

WaveGrip’s G1 multi-packing applicator is helping Florida brewery, Due South Brewing Co. to pack its range of canned craft beer much more efficiently and cost-effectively.

Based just outside of West Palm Beach, Due South was the first full production craft brewery in South Florida and currently operates a 27,000 sqft brewery and taproom. Producing around 5000 barrels a year, with five core brands, Due South supplies bars, restaurants and retail locations across Florida.

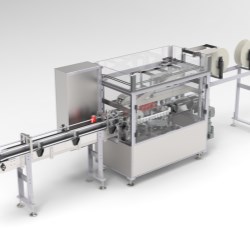

To meet the growing demand for its beers, Due South needed to improve the multi-packing of its 16oz cans in both 4 and 6-pack configurations, all within the limited space available in the brewery. The G1 with its compact footprint of just 1.4m x 0.8m offered the perfect solution, being designed specifically for the needs of small to medium sized brewers and even mobile canning operations.

Due South’s G1 applicator operates at 35 cans per minute (cpm) to fit with the current production requirements of the canning line. With the potential to run at speeds of 100cpm it also has plenty of room for expansion, as Due South’s volume grows for its range of year-round and limited-edition beers.

The G1 has enabled Due South to automate its packaging at an exceptionally affordable price point, moving away from the previously ‘labor intensive’ solution. Positioned as an entry level machine, specifically designed with craft brewers in mind; this has meant Due South predicting it will pay for itself within just 10-11 months.

“Once we installed the G1 our packaging ran much smoother and it saved us a lot of labor at the end of the line. The difference is incredible!” says Mike Halker, founder and head brewer of Due South.

“Above all, the biggest selling point of WaveGrip is their support. They’ve come to our facility a number of times to work with us and to make sure the machine is working as it should. I couldn’t have asked for better service.”

Another important part in Due South’s choice of WaveGrip was that the carriers are extremely lightweight, using less material than any other multi-packing solution. Additionally, all WaveGrip carriers are 100% recyclable and meet current US packaging regulations by being photodegradable.

“Sustainability is obviously important to us and the entire industry. It’s really important that people can come to us and we are able to explain and feel happy in the WaveGrip solution we’re using,” concludes Mike.

Commenting on the partnership Aaron McIvor, WaveGrip’s Managing Director says: “It’s always exciting working with the amazing craft breweries in America and we’re exceptionally proud that Due South chose the G1 for their leading range of beers. We’ve worked hard to design the G1 applicator to be the perfect fit for every craft brewery. Our ability to provide a sustainable, cost-effective multi-pack solution that has truly delivered for Due South is the perfect accolade for WaveGrip.”

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)