- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

WaveGrip’s innovative multi-packing G1 applicator is helping Tupps Brewery streamline its manufacturing process while also providing a sustainable, environmentally friendly solution to the multi-packing of its beer cans.

Based in McKinney, Texas, Tupps Brewery offer a wide range of beers from easy drinking American Wheat and smooth Pale Ales, to an over the top Imperial Stout that sits at 12.1% ABV.

Currently the brewery offers can and keg products and distributes its beers across North Texas, Austin, San Antonio and the state of Oklahoma.

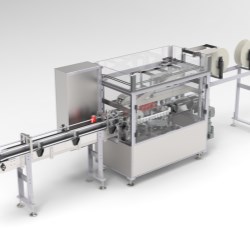

The G1 applicator from WaveGrip was the perfect choice for Tupps Brewery thanks to a top speed of 100 cans-per-minute (cpm), full automation and its easy-to-use design. The G1 has helped improve their manufacturing process and even being run at the current level of 45 – 50 cpm, is providing huge savings in both the cost of materials and in labour.

As well as the improvements in production, the sustainability of the WaveGrip carriers played a large part in the decision-making process for Tupps.

Weighing less than 4g for a standard six-pack and using less material than any other mutli-packing solution, WaveGrip is the lightest carrier on the market. Additionally, all WaveGrip carriers are 100% recyclable and meet current US Packaging regulations by being photodegradable.

“Having an environmentally friendly carrier was a huge factor in our decision-making process. We were really happy with the sustainability of the WaveGrip solution and its environmental story is important to both us and our customers” says Keith Lewis, founder and President, Tupps Brewery.

WaveGrip Managing Director, Aaron McIvor, highlights: “We’re glad brewers are recognizing the environmental impact of packaging and are choosing WaveGrip for their can multi-packing due to its efficiencies and sustainability. The combination of both these benefits is really delivering for breweries and enabling them to maximize their production output with a reduced environmental impact.”

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)