- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

WaveGrip is entering the US market through a strategic alliance with leading can filling and seaming systems provider Palmer Canning Systems.

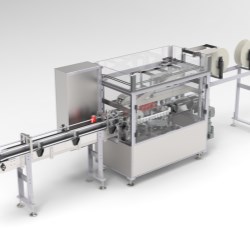

Under the agreement, Palmer Canning will produce G1 and G2 variants of the WaveGrip applicator at its facility in Lafayette, Indiana. People interested in seeing the WaveGrip solutions in person can visit Palmer Canning at the Southern Brewers Conference (booth 213), August 23-25 in Nashville, TN or the California Craft Beer Summit (booth 813), September 7-9 in Sacramento, CA.

WaveGrip dramatically improves the most important aspects of multi-packaging canned beverages with a lighter, stronger, recyclable and photodegradable alternative that is also much more space-efficient than other systems currently available.

Simple, effective and reliable, the applicators can also be integrated at a lower cost, making them suitable for producers of all sizes.

The G2 WaveGrip applicator is capable of collating 500 cans per minute into four, six, or eight packs. The G1 is a hand applicator, ideal for smaller craft producers, which can manually pack more than 50 cans per minute.

Importantly, it also provides an entry-level introduction to the many benefits of WaveGrip, allowing companies to trade up to the automatic applicators as their business grows.

“We’re delighted to be working with Palmer Canning,” comments WaveGrip Managing Director, Aaron McIvor. “We feel the company’s reputation for supporting its customers through canning line technology upgrades is a perfect match for our innovative solutions. Palmer Canning is also renowned for delivering cutting-edge excellence in its own right, such as the counter-pressure can filling systems that deliver accurate fill-volumes, low oxygen and very low spoilage, meaning that products reach customers in the very best condition.”

Mike Palmer, Owner and Founder of Palmer Canning, sees huge potential benefits for customers in a rapidly growing industry. “We feel that can collation has long needed an alternative to established collation technologies. WaveGrip not only offers truly scalable technologies that can grow with the producer, but its offering makes multi-packing cans cheaper, faster and more efficient than ever before. It’s the ideal collaboration for us.”

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)