If this is your company, CONTACT US to activate Packbase™ software to build your portal.

.jpg)

The collaboration between Belsia, a high-quality artisan French potato chip manufacturer, and Ishida, world leader in weighing and packing line solutions for the food industry, underlines the care and support that the company can provide to help small start-up companies achieve a foothold in the market and build a foundation for sustained growth.

Based in Beauce in Northern France, Belsia was established in 2015 when Matthieu and Clémence Maisons decided to devote 10 hectares of the family’s 160-hectare farm to growing the Lady Claire potato variety, whose intrinsic qualities are ideal for the production of high-end potato chips. First marketed in 2016 to local supermarkets, the potato chips, which are hand produced using 100% natural ingredients in four tasty varieties, quickly became a great success, reflected by ever-increasing volumes – 50 tons of potatoes processed in 2016, 150 tons in 2017, 300 tons in 2018 and 500 tons planned for 2019.

An On-going Collaboration

The first contact between Matthieu Maisons and Stéphane Woigt, regional sales manager at Ishida, took place during an exhibition in Paris and a dialogue was maintained during Belsia’s early years, during which time the company relied on second-hand packing equipment to process around 400kg of potatoes per day.

“At Ishida, we do not have large or small customers,” explains Stéphane Woigt. “Instead, we have companies seeking the most suitable and reliable solution for their specific application. In the case of Belsia, when the company first approached us, it was not yet producing a significant enough volume to warrant the purchase of new equipment. However, we remained in regular contact, providing advice and establishing and maintaining a relationship of trust so that, when ready, Matthieu Maisons turned to Ishida to invest in a new potato chip packing line."

As Matthieu Maisons confirms: "We appreciated that an international company like Ishida was willing to give equal consideration to the needs of a young company like ours."

Complete Responsibility

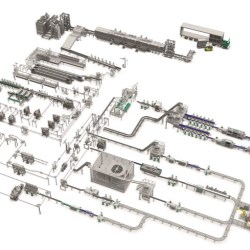

In 2018, after an assessment of three manufacturers, Belsia chose Ishida to devise a complete turnkey line with a small footprint, with Ishida assuming full responsibility for the entire installation and its performance.

During the 1990s, Ishida devised an integrated snacks packing solution, featuring a weigher mounted directly over a VFFS bagmaker to deliver valuable space savings. The multihead and bagmaker work in perfect harmony to deliver the highest speeds, efficiency and pack quality, without compromising Ishida’s proven precision and accuracy.

A Fully Integrated Solution

At Belsia, the line comprises a 10-head Ishida CCW-SE series multihead weigher with polished stainless-steel hoppers and an Astro bagmaker equipped with special stripping plates which clear the seal area before sealing to ensure excellent pack quality and close to zero film waste. In addition, Ishida has supplied a bucket elevator that feeds the potato chips to the weigher and a throat metal detector, positioned between the weigher and the bagmaker, to identify and reject any metal contamination before the potato chips are bagged. Belsia is packing both 150g and 40g bags on its Astro bagmaker.

The new Ishida installation, which is operating at 30 packs per minute for the 150g bag format, has enabled Belsia to increase production to 800kg per day of processed potatoes, combining excellent equipment reliability and minimum downtime for product changeovers with accuracy to within one gram of the target weight, thus avoiding overfills. All these benefits combine to provide substantial savings for the company and a short investment payback

Equally important, the line is scalable and therefore will be able to support Belsia’s ongoing development of its potato chip range to deliver “a new flavour each year”, according to Clémence Maisons.

Customer Satisfaction

Matthieu Maisons concludes: "In addition to the reliability and speed of the line, we also appreciate its ease of use thanks to the intuitive touchscreens. Changing the bagmaker film reel takes only a few minutes and daily cleaning is easy. In our business where a production stoppage can very quickly cause problems, we are able to work with confidence because we know we can rely not only the Ishida equipment but also on Ishida’s fast-response after-sales service."

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)