If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Walking through store aisles, consumers are bombarded with products just like yours. What can you do make your product stand out? Decoration and labels are integral parts of creating brand awareness. They convey pertinent information to the consumer such as instructions for use, key ingredients, and important brand messaging. There are many types of packaging labels you can choose from for your packaging needs. Here, we are highlighting two types of packaging labels: in-mold and pressure sensitive.

In-Mold Labels

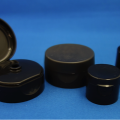

IML & PSIn-Mold Labels (IML) are thin, preprinted, polypropylene (PP) labels or foils that are inserted in an open plastic injection mold and held in place via vacuum ports, electrostatic charge or another method. The mold is closed and the plastic resin is injected to mold the part. The label is permanently integrated within the finished injection molded part. One key advantage of IML packaging labels is that they eliminate the use of adhesives and the issues that adhesives can cause during the application process. IMLs are also more durable and tamper proof, so something like condensation from the product will not cause any issues. These are ideal for use with high volume products because they can make a big impact. IML can be done on any side, top or bottom of a container, giving lots of real estate for your decoration, brand message, etc.

Pressure Sensitive Labels

Pressure Sensitive (PS) labels are one of the most popular labeling methods used. PS labels are self-adhesive, making them very easy to apply, and can be used on virtually any container, regardless of material or shape. These labels are better for small quantities and they can be purchased at low minimum order quantities (MOQs). An advantage of PS labels is that they allow for many special decoration applications such as foil stamping, perforations, scratch 'n sniff and textures. PS labels can also be die-cut into all types of different shapes to follow the contour of the container or create interest.

Labels Can Impact Sales

Your product decoration and labeling matters. The success of your product depends on the message your branding sends. MJS Packaging is equipped to handle all types of labels and wants to help your packaging to stand out on the shelf as much as you do. We will work with you to find the perfect packaging label and decoration to make your product stand out. You can put our experience and industry knowledge to work for you for your label solution by contacting a packaging expert today.