Public

Nordson EFD Catalog

Nordson EFD Catalog for Animal Health Solutions

Nordson EFD Certificates

Nordson EFD Links

Nordson EFD Locations

Nordson EFD News

Nordson EFD Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Nordson EFD, a Nordson company, the world’s leading precision fluid dispensing systems manufacturer, is pleased to introduce its Contact vs. Jet Dispensing white paper.

As products continue to get smaller and smaller, Nordson EFD has developed new solutions to address this growing need to apply precise, repeatable micro-deposits of assembly fluids in production processes worldwide.

“We understand the challenges manufacturers face when their process requires bonding tiny substrates and components together,” said Peter Langer, Business Unit Director of Valves at Nordson EFD. “The deposit tolerance requirements are considerable. And there are a number of variables to consider in order to choose the right dispensing method.”

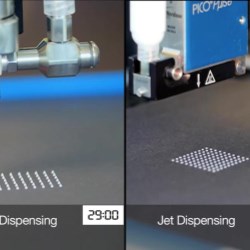

This white paper helps manufacturers understand the difference between two of the most common dispensing methods. Contact dispensing, for example, allows users to dispense extremely tiny amounts of fluid consistently. The tradeoffs include slower cycle rates and possible part damage due to the need for Z-axis movement of an automated system.

Jet dispensing benefits include highly precise, repeatable micro-dispensing at speeds up to 1000Hz continuous. Jetting also meets exact deposit tolerances as small as +/- 1%. Tradeoffs include the fact that some fluids, such as those filled with highly-abrasive particles, cannot be jetted efficiently.

Getting an experienced fluid application specialist involved early in the process of selecting a dispensing system can prevent many issues that could occur later in production.