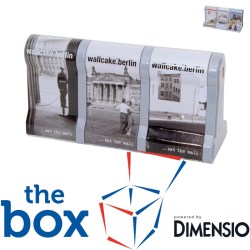

Over the years the box has been able to realize several successful co-creations together with customers. Because a tailor-made look means developing a look together. Fine-tuning, creating, and updating until you have the perfect tin that meets desired wishes and requirements. There are different facets involved in tin packaging that must meet consumer protection guidelines for what is packaged inside, but also wishes regarding the self and online appearance.

1. Mapping out your wishes

Discuss all your wishes and the requirements that the tin packaging team must meet. What product is packaged in it? What is the purpose of the packaging (branding, protection, sustainability, etc.)? The box team can advise on and help determine the desired dimensions of the packaging.

2. Design

A design is created with the correct (house style) colors, style elements, and images. The box regularly sees that customers make the design themselves or have it made, but it is, of course, also possible that the company can arrange this for you.

3. Material selection

The choice of material is essential for the packaging to function optimally and to achieve the desired appearance. As you might not immediately think, there are significant differences in material just in the can. You can choose between different types of metal, such as aluminum and tinned steel. You can also determine the thickness of the material yourself. Of course, the box will advise you on the most suitable material.

4. Prototyping

Based on all material and design preferences, the team will create a 3D sample, so that you have a tangible example of the created design. You can also easily visualize any textures and embossing and debossing. Is the sample completely according to your wishes? Super! Does anything need to be changed? We will then implement your wishes and make a new sample.

5. Production

Once you have approved the sample, production can be started. The box's regular production partners use the most modern production techniques. The metal sheets of the packaging are printed and provided with internal and external lacquers or coatings. The parts are then cut and, if necessary, provided with embossing or debossing, after which they are formed in the chosen packaging.

6. Quality control

Trust is good; verification is better. To ensure that customers are given, sold, or use the correct tin packaging as completely agreed, the company randomly checks production to ensure that the dimensions, colors, and quality are correct as agreed upon.

7. Packaging and shipping

The tin packaging is carefully packaged so that it remains beautiful and is delivered to you or the specified address in perfect condition.

If you're interested in collaborating with the box team to create custom tin packaging for your brand, like many major brands have done, please feel free to reach out.