If this is your company, CONTACT US to activate Packbase™ software to build your portal.

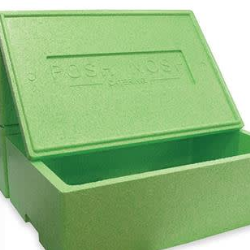

Different materials and products are shipped in different ways and need different levels of protection. For example, large aluminium sections can be shipped loose while LED strips require vital shock protection to survive their journey.

Challenge

Two manufacturers from different sectors (construction and electronic sectors) asked DS Smith to help them to develop transport packaging so that their innovation, made of large aluminium sections with integrated LED strips, could be transported to the USA safely and in its entirety.

Our Approach

To develop a cost-effective, protective packaging that meets the demanding needs of an innovative new product. Once the design is finished we need to convince the manufacturers of our concept. We subjected the packaging to a number of tests in the fully-equipped DS Smith test centre (pack right center). The packaging containing the product underwent a drop test in accordance with the latest standards and the LED's were then fully checked before they were loaded on board the aircraft.

Result

- Better protection as the shock-proof packaging ensures a fragile and valuable product gets to market

- More sales as the customers get their goods quickly thanks to packaging suitable for air transport

- Lower costs because of the improved logistics and warehousing of a stackable solution.

- Better environmental performance due to recyclability of the solution

- Increased cost-effectiveness as the resealable nature of the solution means it can be used multiple times.